In Brazil, it is still a challenge to produce fashion in a sustainable way, mainly because of the high cost of raw materials. But for some young brands, this has not been an obstacle. Two such companies are Movin, based in Rio de Janeiro, and Insecta Shoes of Porto Alegre. With a desire to address the country’s social and environmental problems at the core of their missions, both are members of B Corp Brasil, a certification program that recognizes companies’ responsible practices and their positive effects.

Even before launching Movin at the end of 2011, Pedro Ruffier knew he wanted to create a brand that would, in its design and production, minimize its negative impacts on society and the environment. “The materials and processes used in the production of the clothes are certified as meeting high sustainability and social responsibility standards,” says the businessman, who has been looking for models outside the fashion world from whom he can borrow ideas for his own enterprise. Researching solutions from the automobile industry, he found 3D prototyping, which eliminates the need to produce physical samples, thus reducing textile waste.

The fashion industry usually tries out six or seven pilot pieces of each model until the final product is approved. In contrast, says Ruffier, “At Movin, all the approval is done digitally.” The technology also allows the company to predict how much leftover raw material there will be at the time of cutting, which helps bring waste close to zero. Movin sells 300 pieces per month in multi-brand stores and by e-commerce.

Movin’s clothing is made from relatively sustainable materials such as recycled polyester, biodegradable polyamide, linen and bamboo. The brand’s cotton is grown without the use of chemical fertilizers and pesticides, all of which can affect soil, water and local biodiversity.

Patch leftovers go to NGOs partners and social projects. “This reuse through handicraft generates income and empowerment,” says Ruffier. Other waste, such as cut paper, is recycled into clothing labels and stationery. Even the hanger created by Movin is made of cardboard. “Besides being thin, light and easy to carry, this product is recyclable and much more resilient than the traditional plastic hangers that end up going to the landfill when they break,” he says.

At the brand’s headquarters, each product has a file that includes such details as the materials used, related certificates, the amount of carbon emissions avoided by the production process (compared to traditional production), where the raw material comes from, and pricing. “We do not have to wait for the consumer to uncover this information, as it is the company’s responsibility,” says Ruffier. Disclosing processes, costs and suppliers leads customers to value products much more, encouraging other companies to buy from those producers, which generates benefits throughout the production chain.

Movin’s clothing is made from sustainable materials such as organic cotton (Photo: Movin)

OPEN DIALOG

Transparency is also one of the selling points of Insecta Shoes, the southern Brazilian brand creates vegan (made with no animal products) shoes produced in Brazil from vintage clothing and recycled PET bottle fabrics. The soles are made out of shredded rubber from shoe industry discards.

Every November, the company promotes Green Friday, a counterstatement to Black Friday: Instead of giving discounts, the brand divulges the expense of producing the shoes. “We believe in fair trade, dialogue, respect and transparency so that everyone wins in this relationship,” says Insecta’s founding partner, Barbara Mattivy.

Created in 2014 from an initial investment of US$6200, Insecta has been growing without external capital. The company has two stores of its own (one in São Paulo and another in Porto Alegre) and also sells in multibrand shops in Brazil and abroad, in cities like Los Angeles, New York, Toronto, Berlin and Barcelona. The company had a turnover of US$558,000 last year. For 2017, the forecast is US$950,000.

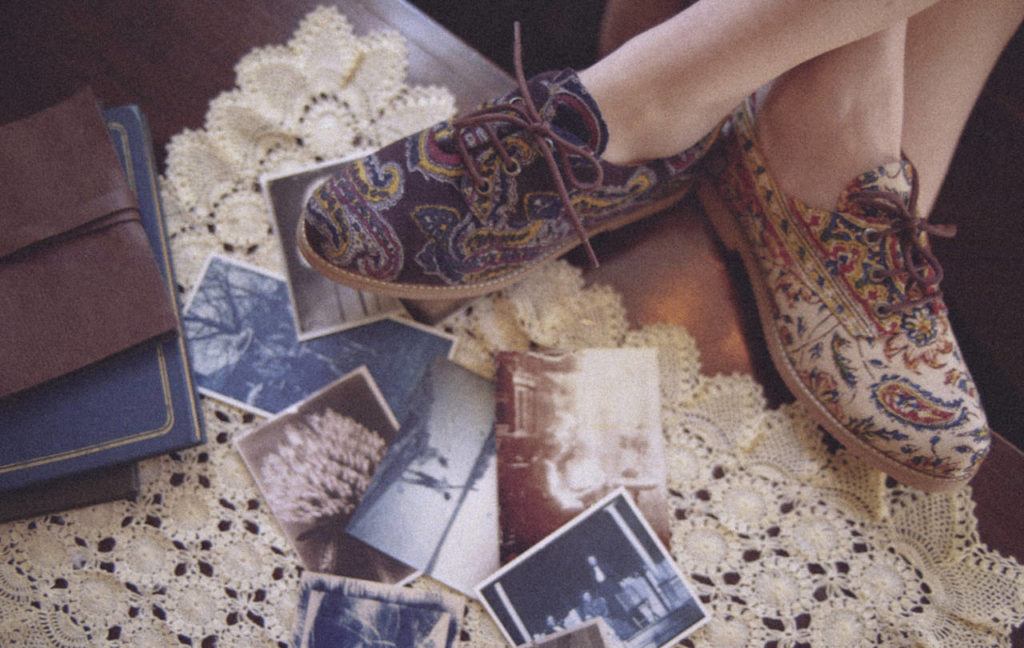

Shoes that are not made with any animal products, but from recycled fabric (Photo: Insecta Shoes)

The use of organic cotton reduces carbon emissions by 46 percent, sediments that acidify soil by 70 percent and water consumption (therefore irrigation) by 91 percent, according to data released by Movin. Linen, another material used in producing the brand’s clothing, is made from the flax plant, which requires 20 times less water than conventional cotton to grow, and uses little to no chemical fertilizer. No chemicals are used in the dyeing of pieces. This process emits 50 percent less carbon than those used by conventional industry.

In its two and a half years of existence, Insecta Shoes has recycled 3,000 pieces of clothing, 900 kilograms (1,984 pounds) of fabric and 2,000 plastic bottles to produce approximately 15,000 pairs of shoes.